Services

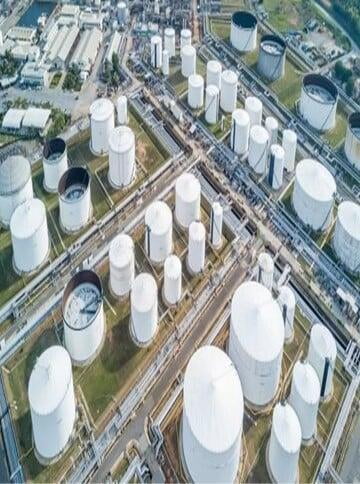

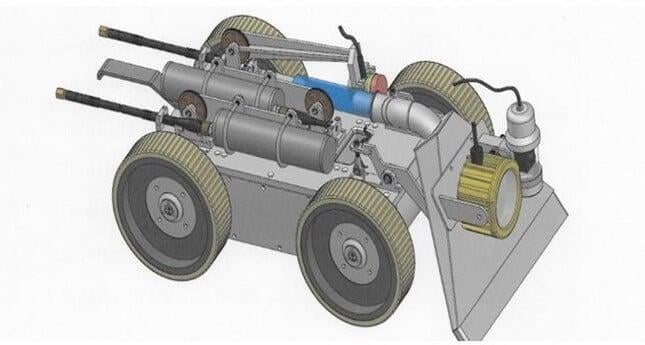

We would like to introduce our company, which specializes in manufacturing Robotics for Above Ground Storage (AST) inspection, in compliance with API requirements. Our goal is to enable testing of ASTs while they are still in service. Our approach involves testing a percentage of the tank bottom, typically around 1.5-2.0%, and then utilizing Extreme Value Analyses (EVA) for the untested portion. This method provides accuracy of 99.1%, surpassing the practices of most inspection companies that do not use EVA.

In addition to our Robotic API inspection tools, we also build tools for non-Robotic API inspections on smaller tanks. These inspections can be conducted by just two individuals in a single day, and the EVA methodology can be applied to all data regardless of the type of machine used. Rest assured, there will be no downtime for the customer during either the testing or machine usage.

Our Robotic Inspection Machine typically takes approximately 4 to 5 months to deliver. However, upon delivery, we will provide on-site assistance for your first job. We will disassemble the machine and guide your team on maintenance and potential repairs, if necessary. Furthermore, we will support you with all administrative forms and provide training on required safety protocols, Extreme Value Analyses, and all post-inspection requirements, including the final report.

To facilitate a comprehensive understanding of our technology and expectations, we can arrange an online discussion. During this discussion, we can address any relevant questions regarding the application of our robotics and the administrative aspects of the inspection process.

Why Robotic Inspection?

To assure that your Storage Tank meets the standards of API and for safe operation.

Corrosion of metallic components indeed has a significant impact on the efficiency of the refining process. Equipment failure caused by corrosion is a major concern, which in turn drives the refinery maintenance schedule. The direct costs associated with corrosion in the U.S petroleum industry were estimated to be around US $3.7 billion in 1996.

Paul Rose Consulting, LLC

Robotic Tank Inspection

1409 Wigeon Way, #206

Gambrills, MD 21054 USA

Phone: 1-443-714-1775 USA

Contact: